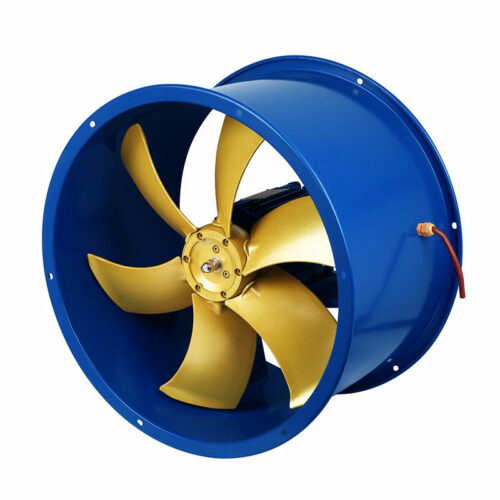

Wood Drying Fan has a novel structure, beautiful appearance, and superior performance.

Applied Conditions

The maximum ambient temperature is no more than 130℃. The maximum relative humidity is no more than 98%.In the ambient of acid-deficient, alkalescent, steam, without combustible gas, the motor can be also used in the vacuum drying equipment, according to the specific conditions.

Standard Form

- Diameter: 400mm,500mm,550mm,600mm,700mm,800mm,900mm and 1000mm

- Power Form: Single phase:220V, Three phases: 220/380/660V, 230/400/690v 240/415

- Frequency: 50/60Hz

- Working Method: continuous (S1) periodic running in positive and opposite directions

- Cooling Mode: ICO141, IC411(Totally Enclosed Fan-cooled)

- Protection Class: IP55

- Insulation Class: Class H (180℃)

- HS Code: 8414599099

Main Features

- Diameter: 400mm,500mm,550mm,600mm,700mm,800mm,900mm and 1000mm

- The angle of the fan can be adjusted according to the client’s requirements

- The fan blades can be a direct connection to the motor

- The circumferential velocity of the impeller does not exceed the condition, there are three different rotational speed:2900r/min,1450r/min, and 960r/min

- Motor: H class 180 ℃ high-temperature resistant. According to the analysis methods of advanced thermodynamics, it not only reduces the electromagnetic loads of the motor but also increases the performance efficiency and energy saving.

- Fan Impeller: 4-8 pieces aluminum alloy blades

- Fan Frame: Aluminum Alloy

- Customized high-temperature resistance

- High-temperature grease is imported from Japan

- Strict inspection before shipment

High-Temperature Motor

- 100% copper motor, with H class insulation (with modified polyester imine enameled wire).

- According to the analysis methods of advanced thermodynamics, it not only reduces the electromagnetic loads of the motor but also increases the performance efficiency and energy saving.

- The motor can be resistant to aging and burnout. It can be operated in high temperature and high humidity vapor environments.

- The motor adopts an external structure injected with lubricating oil. It not only increases the service life of the bearing but also avoids the oillingdisassembly.

- It is designed based on the characteristic of the blower-pump load, the shell adopts aluminum alloy material, and the fastening piece adopts stainless steel and copper, attractive appearance.

- The motor structure adopts the straight shaft extension and subulate shaft extension, special grease lubricant resistant to high-temperature bearing, low noise, and small vibration.

Fan Blade: Aluminum alloy, 4-8 pieces, resistant to rust. Arc and right-angle blades to meet your different demands.

Leave your contact information to get a quotation!