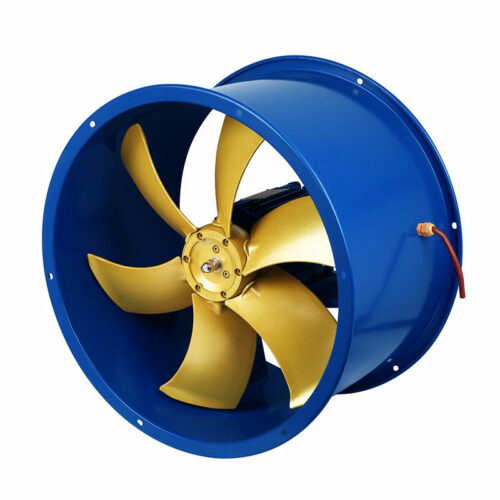

Grain drying fan is made of a cylindrical housing and three flanges. The outlet and inlet follow the air by connecting a pipe network. The inlet wind collector is made of a gradually shrinking streamlined form and a sound-absorbing plate. The outlet has a pre-rotation vane, whose gas has a good airflow distribution and stable pressure resistance. Thanks to the new design of the meridian acceleration, the pressure is higher than an axial fan and the air volume is larger than a centrifugal fan.

Application: CRF grain drying diagonal flow fan with high-temperature resistance is widely used in barking grains, other agricultural, food, industrial, and mining enterprises, hotels, restaurants, museums, gymnasiums, and high-rise buildings for ventilation.

Main Features

- Diameter: 650mm, 700mm, 750mm, 800mm

- Motor: H class 180 ℃ high-temperature resistant

- With pre-rotation vane to achieve flow-distribution and stable pressure resistant

- Convenient installation, the design of meridian acceleration

- Have an invention patent

- HS Code: 8414599099

Core Benefits

- The drying efficiency has been greatly improved: the optimized air volume and air pressure perfectly reach the maximum drying efficiency node of the grain dryer (the traditional dryer uses a centrifugal fan, which reduces the efficiency of the dryer due to excessive heat loss due to excessive air pressure). The drying time of 15T with a diagonal flow fan can be 40-50 minutes less than that of the traditional centrifugal fan, 30T is equipped with two dryers, which can save 100-120 minutes and reduce the fuel cost of farmers.

- The unique and novel appearance design makes the storage, logistics, and installation more convenient: the installation is simple and convenient, which can be easily completed by two or three workers; the weight is light, the transportation is convenient, the volume is small, and the storage space is small, thus reducing the customer’s operating costs; the unique and novel appearance design improves the dryer after matching. The grade makes the product more attractive.

- Low noise: The unique impeller and sound absorption screen design of the product greatly reduce the noise decibels in use, creating a good environmental condition for farmers in the drying process (the noise value of a traditional centrifugal fan in use is more than 110 decibels after testing, and the noise value of diagonal flow unit after optimization is within the normal acceptance range of 85 decibels).

Leave your contact information to get a quotation!